Once again I pass a genuine thanks to not only Matt but all the guys for there are no gals at Ultimate in Mathews for helping me chase and live the American 2 Wheeled Dream. Without them it would be a way harder to be who I am and I may have given up a long time ago.

Tuesday, January 13, 2009

Dura Ace Problem Solved & Created

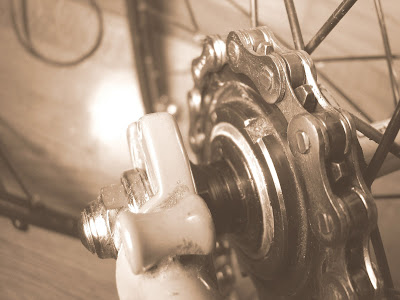

These will be the last new pictures I make/post for awhile, the camera heads to Texas today for a warranty replacement of my broken shutter button. I will miss it and appreciate it's return. look closely and you will see where the c-ring is missing from the million dollar axle

look closely and you will see where the c-ring is missing from the million dollar axle

For the past month or just more I have been fighting strange drive train problems in my rear Dura Ace Track Hub, aka my work wheel. It all started with some crunch I was feeling shortly after doing my thrice a year re-pack of grease back in December. I took it apart for the umpteenth time and found complete corrosion on the drive side bearing and cone only. After putting together the half assed fix at the shop I rolled out and waited for the replacement real parts order to come in which did the other day. After work yesterday evening I went out to see the folks at Ultimate Mathews and work on the rebuild of my wheel which included a brand new Dura Ace million dollar track axle stacked with cones, jams and even new track nuts. Matt saw me coming and had the new axle ready to go in by the time I walked in the door. Zula said, "Roe rooo" to everyone which means hello in her language while I immediately took apart the old. Clean hub cups, brand new 1/4" bearings, pro level bearing grease from the barn and cone wrenches(14mm and 18mm[the old was 14mm and 15mm]) were all laid out in front of me on a big rag. For whatever reason, my child like curiosity I suppose I then proceeded to do something that turned out to be really dumb. I stuck the axle with one side cone and jam on through the empty hub just to see in my mind how it would feel WITHOUT bearings. Just slide it in and twisty turny a bit to feel the smoothness. Well with no bearings to roll on the cone just submerged itself in the hub cup and became stuck. Now I was standing there with my wheel in hand and the new million dollar axle awkwardly stuck in the hub without bearings or grease while Matt genuinely concerned about my front hub was working on that not a few feet away. I looked around for someone to tell me it was gonna be okay. Try again I thought just push it out and get to work. So I did but it did not budge. I started to get sweaty as if I were working for a Pedi Cab company or the bank for that matter. "Matt, where is the mallet?", I asked. Third drawer down I found it and tapped, well okay hit the other side of the axle to drive it back out the way I ignorantly put it in. Yikes, two pieces of my new axle came flying out. The Axle unit itself and a small but what appeared to be important little c-ring that was maybe 1.5mm wide that fit nicely around a groove in the top half of the cone race. My original cones did not have that part engineered into it's manufacture so I was not sure what to do or say. When in doubt ignore all problems and continue the rebuild as if no one noticed. Okay so the tiny little c-ring was gone but the rest of the process went text book perfect. Even without the little part my work wheel feels completely new, smooth on the roll with hardly any float, like Buttah. As well Matt's patience wound up helping me for while I was messing with the rear hub he took apart the front and found that I had 11 bearings on one side and 9 on the other when there are supposed to be 10 on each. Apparently one of bearings traveled through the hub along the axle to join his friends on the other side which would explain that annoying popping sound that I have been ignoring for weeks. He also passed a new used saddle to me that had been passed to him by another mutual friend of ours a long time ago and I cannot wait till that mutual friend notices it and gets a laugh. The Old Fizik I had been sitting on was deteriorating badly leaving the horn exposed all the way down to the hard plastic base. Stay Alive cometh with comfort under arse and smooth rolling wheels, did I mention new rope? That's right I also picked up 2 new Sram PC-7x chains , one on and one in the hole.

For the past month or just more I have been fighting strange drive train problems in my rear Dura Ace Track Hub, aka my work wheel. It all started with some crunch I was feeling shortly after doing my thrice a year re-pack of grease back in December. I took it apart for the umpteenth time and found complete corrosion on the drive side bearing and cone only. After putting together the half assed fix at the shop I rolled out and waited for the replacement real parts order to come in which did the other day. After work yesterday evening I went out to see the folks at Ultimate Mathews and work on the rebuild of my wheel which included a brand new Dura Ace million dollar track axle stacked with cones, jams and even new track nuts. Matt saw me coming and had the new axle ready to go in by the time I walked in the door. Zula said, "Roe rooo" to everyone which means hello in her language while I immediately took apart the old. Clean hub cups, brand new 1/4" bearings, pro level bearing grease from the barn and cone wrenches(14mm and 18mm[the old was 14mm and 15mm]) were all laid out in front of me on a big rag. For whatever reason, my child like curiosity I suppose I then proceeded to do something that turned out to be really dumb. I stuck the axle with one side cone and jam on through the empty hub just to see in my mind how it would feel WITHOUT bearings. Just slide it in and twisty turny a bit to feel the smoothness. Well with no bearings to roll on the cone just submerged itself in the hub cup and became stuck. Now I was standing there with my wheel in hand and the new million dollar axle awkwardly stuck in the hub without bearings or grease while Matt genuinely concerned about my front hub was working on that not a few feet away. I looked around for someone to tell me it was gonna be okay. Try again I thought just push it out and get to work. So I did but it did not budge. I started to get sweaty as if I were working for a Pedi Cab company or the bank for that matter. "Matt, where is the mallet?", I asked. Third drawer down I found it and tapped, well okay hit the other side of the axle to drive it back out the way I ignorantly put it in. Yikes, two pieces of my new axle came flying out. The Axle unit itself and a small but what appeared to be important little c-ring that was maybe 1.5mm wide that fit nicely around a groove in the top half of the cone race. My original cones did not have that part engineered into it's manufacture so I was not sure what to do or say. When in doubt ignore all problems and continue the rebuild as if no one noticed. Okay so the tiny little c-ring was gone but the rest of the process went text book perfect. Even without the little part my work wheel feels completely new, smooth on the roll with hardly any float, like Buttah. As well Matt's patience wound up helping me for while I was messing with the rear hub he took apart the front and found that I had 11 bearings on one side and 9 on the other when there are supposed to be 10 on each. Apparently one of bearings traveled through the hub along the axle to join his friends on the other side which would explain that annoying popping sound that I have been ignoring for weeks. He also passed a new used saddle to me that had been passed to him by another mutual friend of ours a long time ago and I cannot wait till that mutual friend notices it and gets a laugh. The Old Fizik I had been sitting on was deteriorating badly leaving the horn exposed all the way down to the hard plastic base. Stay Alive cometh with comfort under arse and smooth rolling wheels, did I mention new rope? That's right I also picked up 2 new Sram PC-7x chains , one on and one in the hole.

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment